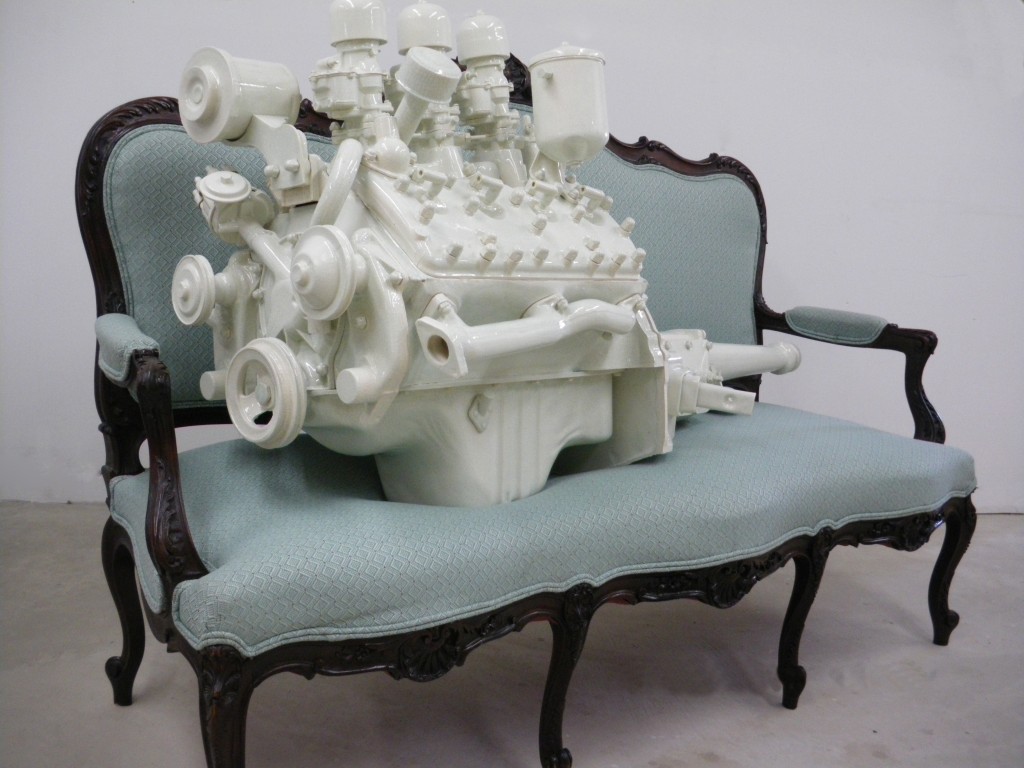

First pour

This is the first pour of the differential from the 12 bolt chevy. On the “size scale” this one is probably 6 out of 10 and is still a lot of work. when finished I think that it will be about an eight piece mold. You can see the blue foam sticking out of the top of the mold, i do that to create some voids in the plaster and to help keep the weight down. Once the plaster has cures I’ll pull it out.